|

|

||

|

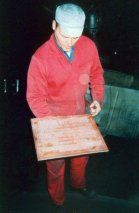

A resin master or 'pattern' of the plaque is first made and this is used to create the mould for the casting. Above you see the master after it has been removed from the newly formed mould, seen on the right. A weighted lid is then placed on the mould in readiness for the molten bronze being poured in.

|

||

|

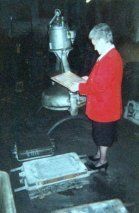

The crucible of molten bronze is carefully checked for correct temperature and scum removed from the surface before it is lifted out of the heat.

|

||

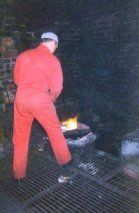

| The bronze is then poured into the mould and left for at least 24 hours to cool. No one can be sure of the final result until the weighted lid is removed. A good deal of finishing work then needs to be done which ends with creating the wonderful patina and burnishing. | ||